Filtration Solutions for

Cannabis Oil Production

CBD oil, or Cannabidiol, is derived from hemp and marijuana plants. The oil is used as an herbal supplement and is promoted to provide a range of health benefits including relief from anxiety and pain.

After CBD oil is extracted from plants and refined, it can also be used in the production of variousfoods, beverages, skin care products, and beyond.

The CBD industry and demand for new products is growing very quickly as consumers become increasingly aware of the health benefits. Also, peoples' attitudes towards the use of CBD has trended more positively.

Extraction Process

To produce CBD oil, the compounds must first be extracted from the plants.

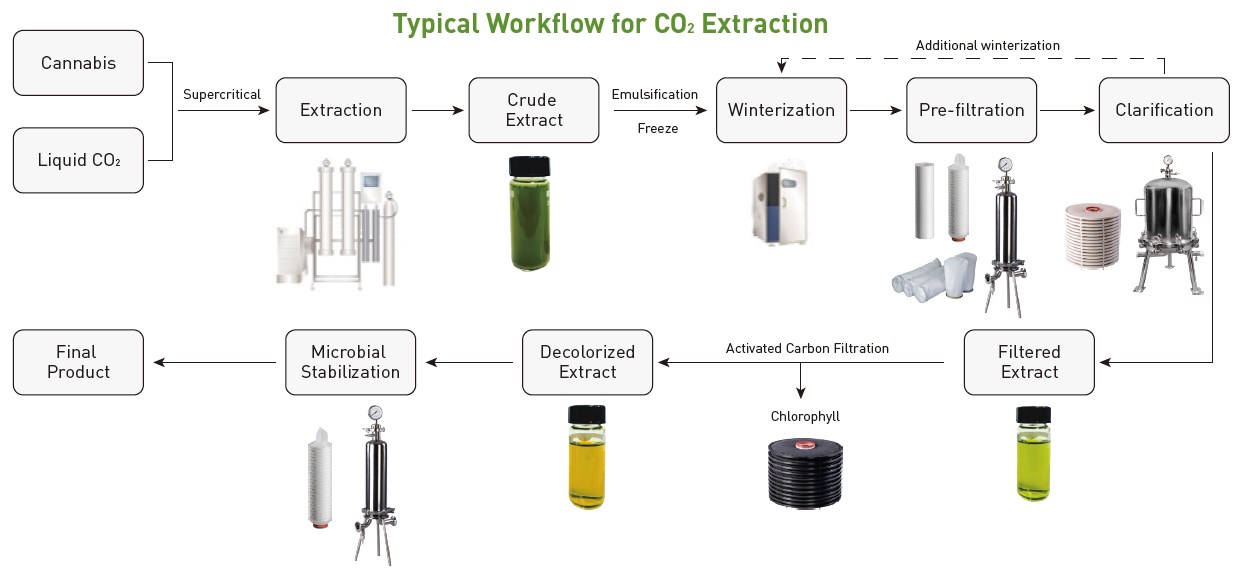

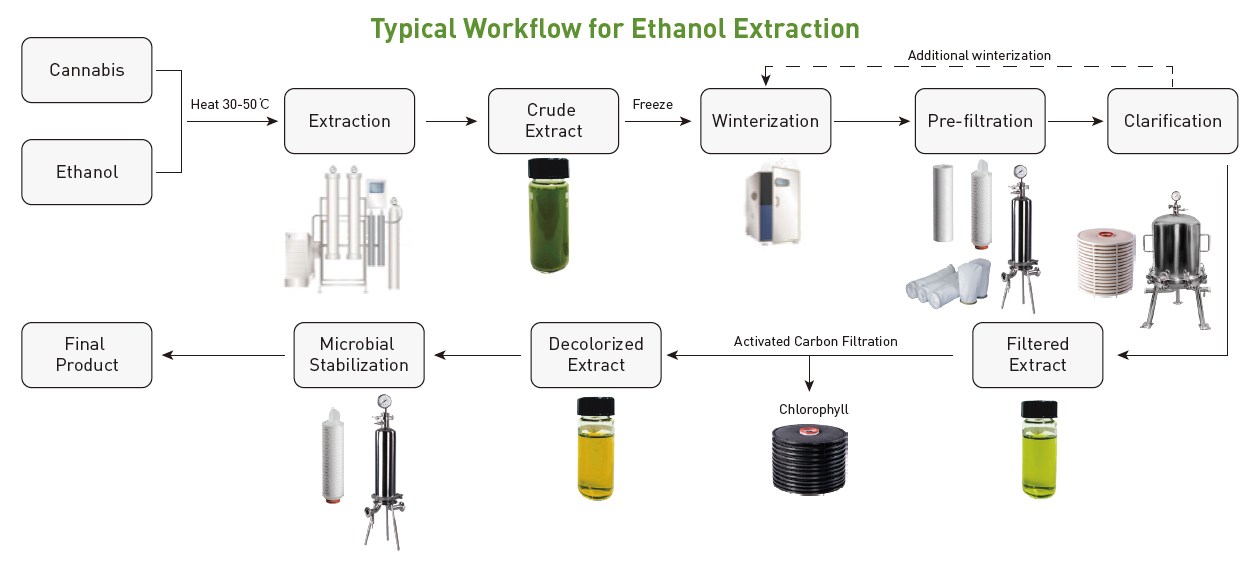

There are several ways to extract the oil, however, the two most common methods are CO₂ extraction and ethanol extraction. In CO₂ extraction, “supercritical” CO₂ acts like a solvent, to flush out the active ingredients from the plant matter. In ethanol extraction the cannabis flowers and leaves are soaked in ethanol, agitated, and strained.

After extraction, the oil undergoes a “winterization” process where the oil is chilled to -40°C to further purify and refine the extract to increase its quality and value. At the cold temperature, the plant waxes and fats separate and harden, allowing them to be more easily removed with subsequent filtration and decolorization steps.

Shown below is the typical workflow diagram for each extraction method.

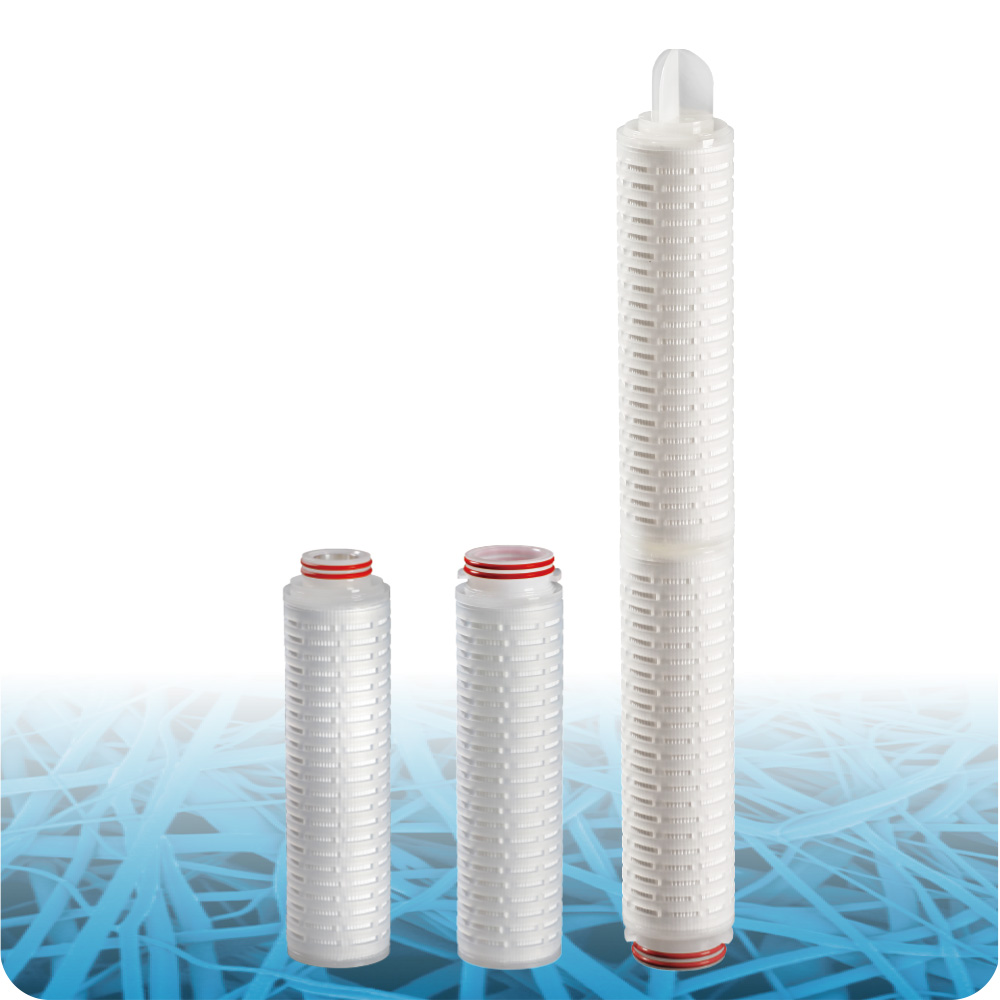

Pre-filtration

During extraction, the crude oil can be separated from the largest particulate matter and plant solids by coarse straining or using filter bags. Following this, Endoer recommends E-PP-A/N Series PP (polypropylene) pleated depth media filter cartridges. These cartridges are produced of a submicronic fibrous matrix and do not contain any binders, adhesives, plasticizers, or surfactants. The filter media and end adapta-tions are thermally welded for strength and integrity, producing filter cartridges with minimal extractable substances. PGA cartridges can be repeatedly hot water sanitized.

Stainless steel filter housings for single or multiple cartridges can be selected, based on the required process flow.

Clarification

To produce high-quality stable CBD oil, Endoer recommends E-DS Series Depth Stack Media Filter Cartridges to remove waxes, fats, and particulate present after the winterization process.

Depth-Stack cartridges are constructed from filter sheets having a unique gradient-density matrix formulated to provide an excellent combination of surface and depth filtration, and absorption. Contaminants are trapped on the surface and within the thickness of the cellulose sheet media, while haze forming oils adhere to a filter aid impregnated within the sheet. To facilitate operation and handling, the media is assembled into a modular format that fits into an housing for sanitary operation and servicing.

Color Removal

After clarification, a carbon treatment step helps achieve the desired golden hue in the oil by removing the green color from chlorophyll in the cannabis plant. E-DSC Series Depth Stack Media Filter Cartridges with Activated Carbon save labor and avoid the messiness of using bulk carbon powder or granules. They also protect operators from exposure to airborne dust from these bulk powders.

Microbial Stabilization

As the last control step prior to packaging, a microbial stabilization stage uses a final filter to remove spoilage and indicator organisms which can adversely affect taste and perceived quality of the oil. This process step assures the product is fresh, clear, and has the longest possible shelf life.

For this stage, we recommend PP pleated filter cartridges with 0.2µm nominal rating or 1µm absolute rating to remove substantially all microorganisms in CBD oil. Select the quantity and length of cartridge to satisfy the flow requirement, for installation in a sanitary-type stainless steel filter housing. This type of installation lends itself to a high-quality, sanitary, low-waste, and robust oil production process.

Sterile Air Filtration

One additional step is important to keeping the processing and packaging environment protected from unwanted microbial contamination. Maintaining sterile air filtration on the system vent ports keeps airborne organisms from entering the filter housings and process vessels. This is standard practice in pharmaceutical and food/beverage production processes.

PTFE membrane filter cartridges are the preferred choice for this application. The hydrophobic nature of the membrane assures low-resistence to passage of air without risk of blockage due to surface wetting. The proven microbial retention assures near total elimination of potential contamination. Filters can be steamed and tested easily and repeatedly to maintain cleanliness and integrity standards.

Cannabis Filtration Equipment

To save floor space and operate more efficiently, Endoer offers cannabis filtration systems that combine stages of pre-filtration, clarification, color removal, and microbial stabilization. We can offer standardized systems or provide one to your exact requirements. We can save you the effort and costs of designing and configuring a system that may or may not meet your needs. Please contact your Endoer representative to learn more about how our products can make your process more productive and cost efficient.