Constructed of 100% perfluoroalkoxy (PFA) for an extraordinary degree of chemical tolerance in critical micro-electronics applications. A ring nut closure provides a secure seal and ease of servicing. Accepts 10" nominal length 222/FLAT configured cartridges. Provides the optimal performance and compatibility available for chemical and temperature tolerance.

Features

- Maximum tolerance to the harshest acids, bases, and organic compounds.

- Non-restrictive fluid flow.

- Usable with temperatures up to 212°F (100°C)

- Multiple levels of cleanliness available to provide extraordinarily low extractable substances

Applications

- Critical process fluids in micro-electronics and semiconductor manufacturing

- Laboratory water and ultra-high purity water requiring the lowest attainable extractable substances

Product Quality

- Manufactured within an ISO 9001:2015 certified quality management system

- •Inspected, qualified, and packaged in a clean room environment.

- Certification of Quality document provided upon request.

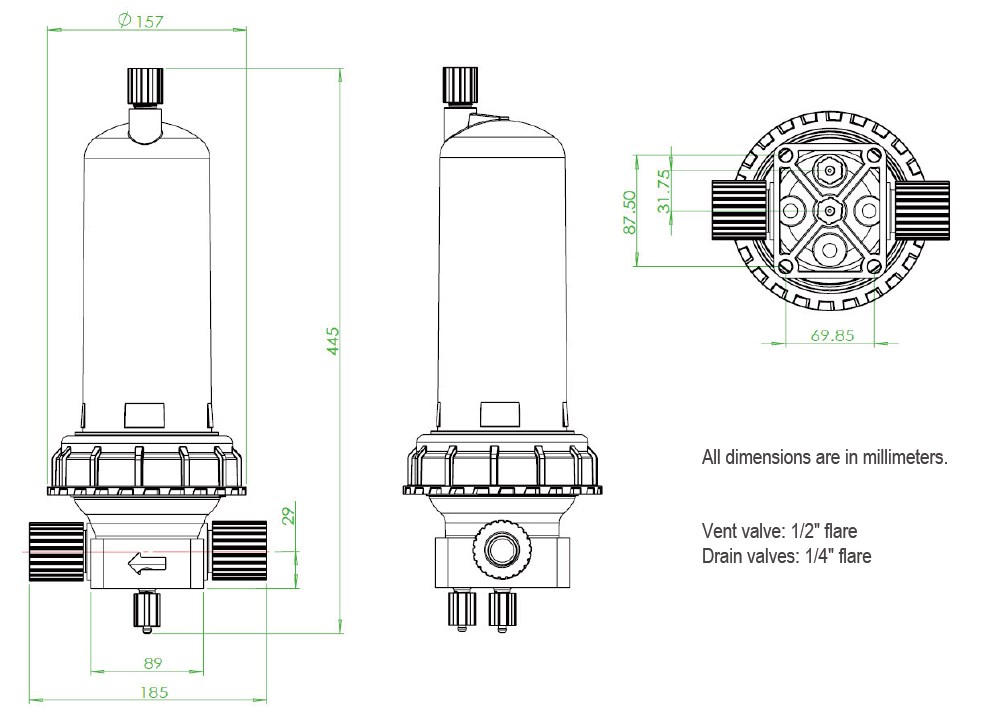

Dimensions

Materials of Construction

| Head, Sump, Ring Nut: | Perfluoroalkoxy (PFA) |

| Seal: | PTFE encapsulated FKM |

Operating Conditions

| Operating Temp., Max: | 45 psi (3 bar) at 100°C (212°F) 110 psi (7.5 bar) at 25°C (77°F) |

Cleanliness Level Options

Cleanliness level identifiers indicate the type and degree of soaking and rinsing performed to achieve the stated degree of extractable substances.

Level R0 . . . Rinsed with 18MΩ UPW to control effluent particle counts.

Level R1 . . . Acid cleaned and rinsed with 18MΩ UPW to control effluent particle counts, TOC <5ppb, and metal ionic substances to below 40ppb.

Level R2 . . . Acid cleaned and rinsed with 18MΩ UPW to control effluent particle counts, TOC <5ppb, and metal ionic substances to below 25ppb.

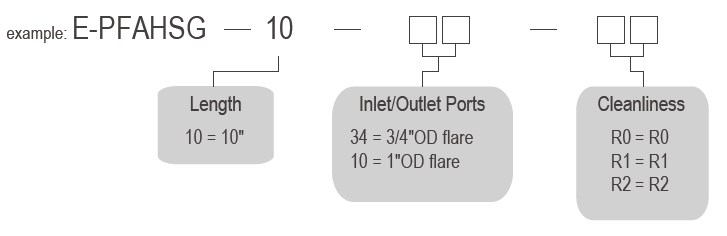

Ordering Information