Endoer's SC-series filter cartridges are constructed of 100% stainless steel in both pleated and cylindrical geometries. When your application operates at high temperature and needs a filter that tolerates high differential pressure, Endoer offers you multiple design options. These rugged designs can handle repeated physical cleaning, chemical cleaning, and back-washing cycles for years of reliable use.

Construction Options

- Pleated Woven Mesh /#E-SCPWM Series

- Available alloy options: 304, 316, 316L

- Pleated Sintered Fiber /#E-SCPSF Series

- Offers the best economy in all-AISI316L construction

- Pleated Sintered Mesh /#E-SCPSM Series

- Triple-layer construction can be back-flushed most effectively.

- Sintered Powder,Cylindrical /#E-SCSPC Series

- Ratings down to 0.3um. Surface can be easily scrubbed.

Features

- 100% stainless steel construction

- High tolerance to heat and differential pressures

- Each cartridge receives a 5-step cleaning process to assure freedom from particulate and contamination

- Electropolished finish

- Available heavy-duty core option

- Retention ratings from 0.3 to 40 microns

Applications

- High temperature fluids

- Steam

- Cryogenic fluids

- Molten polymers

Dimensions

| Diameter: | 64mm (2.5") nominal |

| Lengths: | 10”, 20”, 30”, 40”, & custom lengths |

Materials of Construction

| Media & Hardware: | AISI316, 316L, or 304 Stainless Steel |

| Seal Options: | FKM, E-FKM, NBR, EPDM, Silicone |

Operating Conditions

| Operating Temperature | 215°C (420°F) max. ** |

| Operating dP (max.) | 10 bar (150 psi) @ 100℃ (212℉) / standard core 16 bar (235 psi) @ 100℃ (212℉) / heavy-duty core |

| Servicing dP | 4.1 bar (60psi) @ 100℃ (212℉) |

Product Quality

- Individual elements are tracked by serial number.

- Manufactured within an ISO 9001:2015 certified quality management system.

- Certificate of Quality document is provided with each production lot.

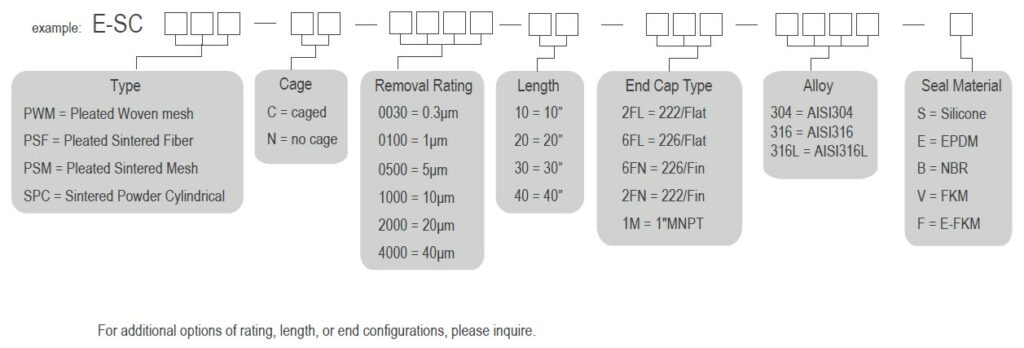

Ordering Information