MicroDoer™ PFA Series Electronics Grade PFA/PTFE Pleated Filter Cartridges 100% fluoropolymer

MicroDoer™ PFA series pleated filter cartridges are constructed of 100% fluoropolymer membrane and hardware for ultimate performance in the most demanding microelectronics applications.

They deliver extraordinary chemical comp...

MicroDoer™ PFA series pleated filter cartridges are constructed of 100% fluoropolymer membrane and hardware for ultimate performance in the most demanding microelectronics applications.

They deliver extraordinary chemical compatibility, heat tolerance, and filter cleanliness. Available in industry leading effective filtration areas of 0.9sqm (9.7sqft) and 1.12sqm (12.1sqft). Product purity is assured with proven ultra-low extractable TOC and ionic substances. Cartridges are 100% integrity tested to assure optimized retention performance.

Features

- 100% fluoropolymer, with PTFE membrane and PFA hardware.

- Ultimate chemical compatibility and heat tolerance.

- Proprietary acid treatment and extended duration 18 mega-ohm rinse assures lowest degree of extractable substances.

- Available in a hydrophilic membrane option for ease of wetting aqueous uses.

Applications

- Aggressive wet-etch solutions

- Concentrated acids and caustics

- Oxidizers; ozonated solutions

- Fine chemical filtration

- Ultra-pure process water production

- Plating solutions

Product Quality

- Each membrane filter element is individually tested for integrity by diffusion flow.

- Individual elements are tracked by serial number.

- Produced in a clean-room environment for product purity & cleanliness.

- Manufactured within an ISO 9001:2015 certified quality management system.

- Certificate of Quality document is provided with each production lot.

Materials of Construction

| Media | PTFE |

| Support Layers | PTFE |

| Cage/Core/End Caps | PFA (polyfluoroalkyl) |

| Seal Options | E-FKM |

Dimensions

| Diameter | 69mm (2.72") |

| Lengths | 10”, 20”, 30”, 40” |

| Filtration Area | 0.9 m² (9.7ft²) per 10” element (Standard) 1.12 m² (12.1ft²) per 10” element ("H" option) |

Operating Conditions

| Operating Temperature | 185°C (365°F) max. |

| Operating dP (max.) | 4 bar (58 psi) @ 20°C (68°F),2 bar (29 psi) @ 80°C (176°F) |

| Change-Out dP | 2.6 bar (38 psi) @ 20°C (68°F) |

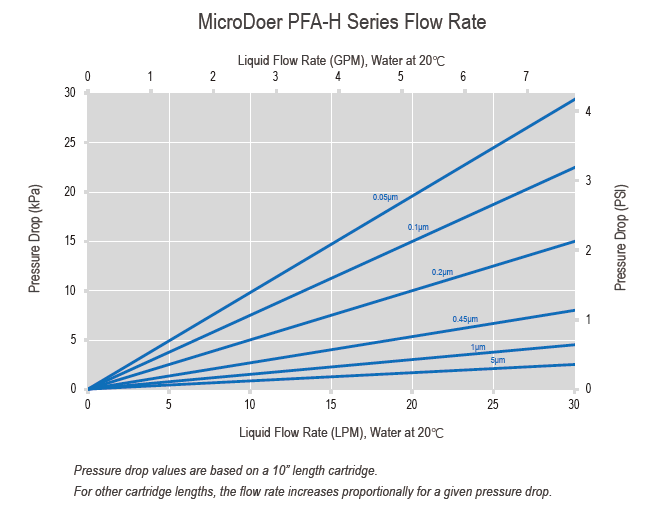

Clean Pressure Drop

Effluent Quality

| Particulate Release | ≤ 2 /ml at ≥0.2μ ≤ 1 /ml at ≥0.5μ |

| TOC | non-detectable |

| ionic metals | <15 ppb |

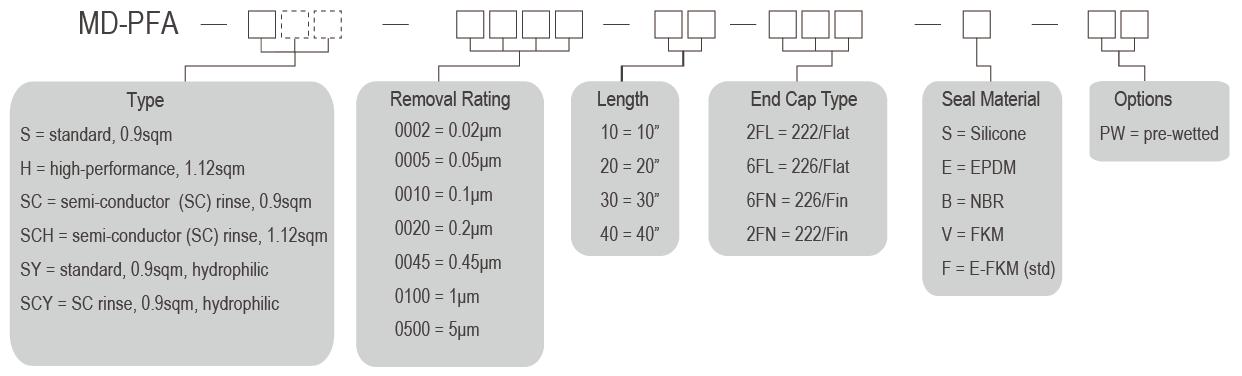

Ordering Information